In the global fresh-produce trade, bananas are one of the most sensitive and quality-dependent commodities. Yet, many importers face the same recurring issues: inconsistent sizing, color-stage mistakes, skin defects, premature ripening, and container-level losses. These problems often stem from poor understanding—or misrepresentation—of what export-grade bananas actually are.

Whether you import for wholesale markets, supermarket chains, or ripening facilities, knowing how to inspect bananas before loading is the key to profitable business. This guide explains the exact standards used globally to define true export-grade bananas and how to avoid costly mistakes.

1. What “Export-Grade” Means in Banana Trade

Export-grade bananas meet internationally accepted standards for size uniformity, skin condition, maturity, hygiene, and packing. They must be capable of surviving long-distance transit (15–35 days) without premature ripening or developing defects.

Export-grade bananas MUST meet:

- Proper finger length

- Uniform curvature

- Correct maturity index for long transit

- Clean, defect-free skin

- Hygienic post-harvest handling

- Ventilated, moisture-resistant packing

- Pre-cooling before container loading

- Chilling Injury in Banana Pulp and Peel

Anything below these benchmarks leads to post-arrival losses.

2. Standard Export Sizes: What Importers Should Expect

Typical Cavendish export grades:

| Grade | Length | Curvature |

| 22–25 cm (Premium Export) | Highly curved | Ideal for GCC and high-end retail |

| 25–28 cm (Super Premium) | High curvature | Preferred in EU / premium markets |

| 18–21 cm (Standard Export) | Medium curvature | Used in Asian markets |

Smaller or irregular sizes often reduce market value.

3. Maturity Index: The Most Critical Quality Parameter

Maturity index determines firmness, sugar development, and shelf life.

| Index | Stage | Export Suitability |

| 4–6 | Mature but raw | Best for export |

| 7+ | Over-developed | Not suitable |

| 1–3 | Underdeveloped | Poor flavor, poor ripening |

Maturity index errors can destroy an entire shipment.

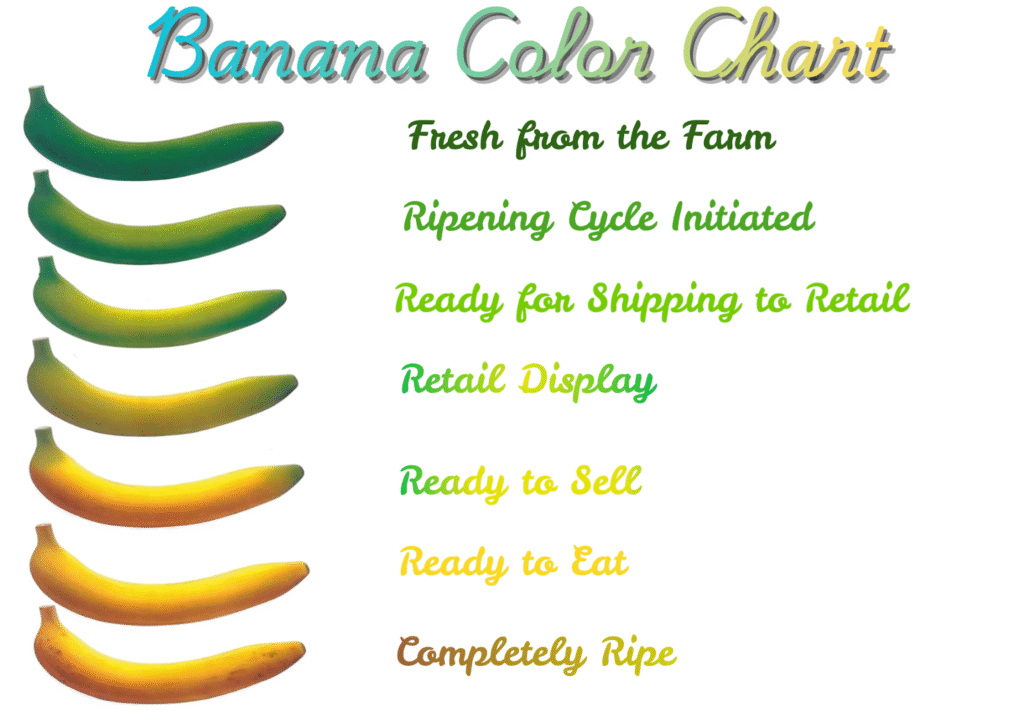

4. Color Stage at Packing: The Secret Behind Shelf Life

Color stages determine ripening behavior.

- Stage 1–2: Dark, early stage — used for long routes (Europe)

- Stage 2–3: Ideal for Middle East & Asia

- Stage 4+: Risky for export

Importers MUST specify preferred color stage before order confirmation.

5. Defects That Downgrade Bananas Immediately

Common defects that disqualify fruit from export:

- Crown rot

- Scarring

- Sunburn marks

- Latex stains

- Mechanical injury

- Uneven ripening

- Mold or fungal spots

- Peeling dents

- Scuffed skin

- Pest marks

A single carton with defects can reduce buyer confidence significantly.

6. Post-Harvest Handling: Where Quality Is Won or Lost

The difference between export-grade and waste-grade often comes down to the packhouse.

Key steps:

- Washing

- De-sapping

- Sorting by size

- Stainless steel contact

- Pre-cooling at 13–14°C

- Carton-level QC

- Palletizing

- Loading into reefer at 13°C

Any break in cold chain = loss of shelf life.

7. Exporter Checklist Importers Should Demand

Before finalizing a shipment, ask for:

✔ Real photos of the actual farm

✔ Packhouse certification (APEDA, GAP, ISO)

✔ Batch sample videos

✔ Packing line photos

✔ Temperature logs

✔ Loading photos

✔ Container seal photo

✔ QC checklist copy

Reliable suppliers will provide these proactively.

Conclusion

Understanding export-grade bananas is the #1 way importers reduce losses, increase margins, and establish a strong supply chain. Armed with this knowledge, you can now negotiate better, inspect better, and choose suppliers with confidence.